Precision in Motion: A Guide to Heavy Equipment Assembly in Factories

In the world of industrial manufacturing, heavy equipment assembly is where engineering excellence meets brute strength. These massive machines—whether designed for mining, construction, or production—are not simply dropped into place. Instead, they’re methodically built, tested, and fine-tuned within factory environments. Precision is not just preferred; it’s essential. From safety to performance, everything depends on getting the assembly right.

Whether you’re a plant manager, engineer, or part of the operations crew, understanding the fundamentals of heavy equipment assembly ensures your facility runs like a well-oiled machine. Let’s explore how this intricate process unfolds and the best practices that bring it all together.

The Importance of Proper Assembly

Heavy equipment—like turbines, crushers, press machines, and large-scale conveyors—consists of thousands of intricate parts, each with a designated function. From bolts and brackets to bearings and beams, every component must be placed with precision. Errors in assembly can cause more than just delays—they can trigger costly equipment failures, safety hazards, or even structural damage. That’s why professional millwright and rigging services in Salt Lake City are essential for ensuring each installation is executed flawlessly and efficiently.

When done correctly, expert assembly delivers:

- Optimal operational performance

- Longer equipment lifespan

- Reduced unplanned downtime

- Enhanced worker safety

- Full compliance with industry regulations

See also: Advantages of Optical TPU Technology for Clear Bra Owners

Pre-Assembly Planning: The Blueprint for Success

Before a single part is moved into position, detailed planning takes place. This phase is where engineering meets logistics.

Key steps include:

- Reviewing Technical Drawings: Engineers and technicians study the design schematics, ensuring everyone understands how each component fits together.

- Creating an Assembly Timeline: A step-by-step schedule outlines what gets assembled when and by whom.

- Inspecting Components: Every part must be verified for quality and dimensional accuracy before use.

- Staging Tools and Materials: Proper tools—torque wrenches, hydraulic lifts, alignment jigs—are staged in advance to streamline the process.

The Assembly Process: A Step-by-Step Approach

1. Foundation and Framing

The foundation is critical, particularly for stationary machinery. It must be level, structurally sound, and capable of supporting immense weight and vibration. Framing comes next—this includes structural supports, frames, and mounts that form the skeleton of the equipment.

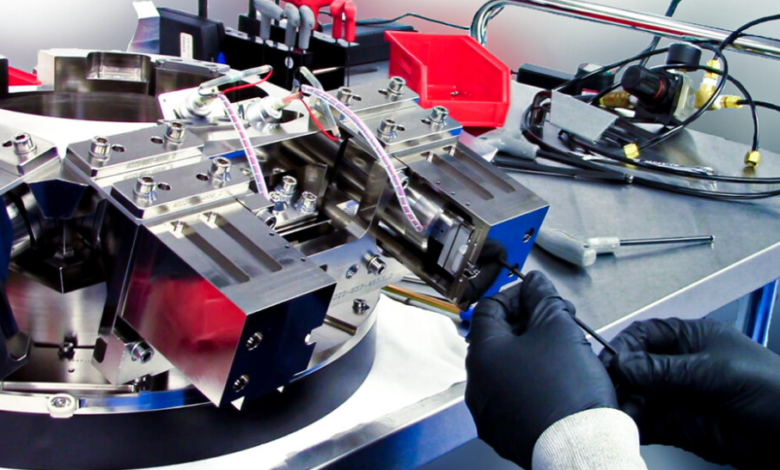

2. Component Integration

With the frame in place, major components are installed. These include motors, gearboxes, shafts, or hydraulic systems. Proper alignment and secure fastening are essential here, as even minor misalignments can cause premature wear or system failure.

3. Electrical and Hydraulic Connections

Modern heavy equipment relies heavily on electrical systems and hydraulics. Technicians route and connect wiring harnesses, control panels, hoses, and valves. Each connection is tested to ensure accurate function and no leaks or faults.

4. Calibration and Testing

Before putting the equipment into service, it undergoes calibration and a battery of tests. These might include:

- Load testing

- Functionality checks

- Safety interlock verification

- Noise and vibration analysis

5. Final Inspection

A thorough inspection is conducted to confirm the equipment meets all manufacturer specs, safety requirements, and operational benchmarks. Only after passing this final check is the machine considered production-ready.

Safety First: Protecting Teams During Assembly

Working with heavy parts and powerful tools comes with risks. To mitigate danger, plants must prioritize safety throughout the assembly process:

- Clear Safety Protocols: Every technician must follow lockout/tagout procedures and wear proper personal protective equipment (PPE).

- Lift Assistance: Cranes, hoists, and rigging systems reduce strain and minimize the risk of injury when moving large parts.

- Team Communication: Radios and hand signals ensure coordination among team members handling complex or simultaneous tasks.

Common Challenges and How to Overcome Them

Despite meticulous planning, issues can still arise. Here are a few common challenges and their solutions:

- Misaligned Components: Use laser alignment tools and follow manufacturer tolerances strictly.

- Missing Parts or Delays: Keep a detailed inventory and work closely with suppliers to avoid supply chain disruptions.

- Inconsistent Assembly Quality: Use checklists, supervisor sign-offs, and repeatable processes to ensure uniform standards.

Post-Assembly Support: Training and Maintenance

Once the equipment is operational, the work isn’t over. Operator training is essential for safe and efficient use, while routine maintenance must begin immediately to preserve equipment life.

Set up a maintenance schedule that includes:

- Lubrication routines

- Regular inspections

- Performance audits

- Component replacements at set intervals

Final Thoughts

Heavy equipment assembly is a blend of engineering, precision, and teamwork. In the high-stakes environment of industrial manufacturing, each piece must come together flawlessly. With careful planning, skilled labor, and a focus on safety, your facility can ensure its machines not only start strong but continue to perform reliably for years to come.

From foundations to fine-tuning, every detail matters. That’s what turns heavy machinery into industrial powerhouses—and factories into production legends.