Inductive Proximity Sensor: Key to Efficient Industrial Automation

Inductive proximity sensors are vital components in modern industrial automation, playing a crucial role in detecting the presence of metallic objects without any physical contact. These sensors are widely used in various applications, from manufacturing to robotics, offering a highly reliable, accurate, and cost-effective solution. By eliminating mechanical wear and tear, inductive sensors enhance the durability and efficiency of automation systems. If you’re looking for high-quality proximity switch solutions, explore https://www.omchsmps.com/de/path/proximity-switch/ from OMCH. In this article, you will explore the working principles of inductive proximity sensors, their various applications, and how businesses can benefit from incorporating them into their industrial operations.

What is an Inductive Proximity Sensor?

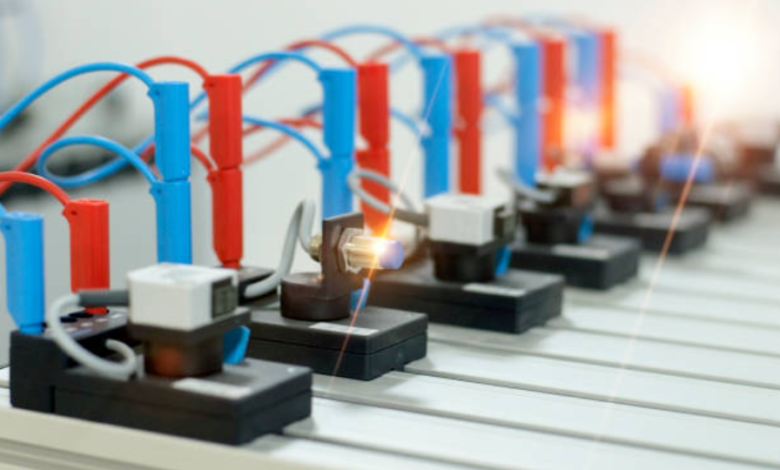

Simply put, an inductive proximity sensor helps in identifying approaching metallic objects by using an electromagnetic field. The sensor has a coil wound on it, which serves an electric current. This creates a magnetic field, and when a metallic object approaches the sensor, the sensor detects the induction changes and yields an output signal. Like most inductive sensors, these sensors are easy, fast, and dependable. Therefore, they are perfectly suited for a range of industrial purposes that require high efficiency.

Indirectly, these sensors also solve the major problem of maintenance costs associated with traditional mechanical devices. Inductive proximity sensors do not come into direct contact with the object being sensed, eliminating wear over time and saving on maintenance efforts and expenses.

How Do Inductive Proximity Sensors Work?

Active detection sensors make use of inductive proximity sensors that rely on inductive techniques. An electric current or electromagnetic field is produced as a result of the technological movement. Moreover, the sensor consists of a wire coil that alters the flow of magnetic energy. When changes happen to the electromagnetic field by adjusting the position of the metal item, which is usually rectangular in shape, closer to the sensor, it results in the modified value of current within the coil. This effect is known as the direct alteration in the level of current and the circuited components of the sensor note this change to produce an action signal.

There are two distinguishing aspects of an Inductive proximity sensor which are:

- Detection Circuit – Responds to a metallic object by changing its position relative to an approaching coil system that generates a magnetic field.

- Oscillator – Employed when a magnetic field that surrounds the sensor needs to be generated.

Inductive proximity sensors have wide scope of application especially in sensing metals like ferrous and non-ferrous items such as steel, aluminium, copper, but one remarkable advantage is in the ferrous materials where induction works with magnets.

Applications of Inductive Proximity Sensors

Inductive sensors are utilized in many industries, semiconductors, terminal operators, automotive and aeronautics among others. These sensors have some of the following key applications in which their employment is essential:

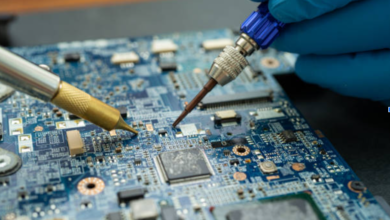

Industrial Automation and Manufacturing

Inductive proximity sensors are used to determine the position or the presence of metallic pieces in an industry or an automated setup. They are, for instance, mounted on conveyor belts to detect the position of metal parts, and thus enable the automation of processes like sorting and treatment for subsequent processing. Also, automated assembly lines make use of these sensors for both the accurate position verification of machine elements as well as the proper orientation of products for the succeeding operation.

These sensors are also used in conjunction with other processes to increase control over the functioning of different machines, like rotating tools, robotic arms and other units in an automated production line, because they enable detection of most elements easily, rapidly and accurately, and as such the degree of control and thus production efficiency greatly increases.

Automotive Industry

Inductive proximity sensors are of great importance in the automotive industry as these sensors are used for position tracking, speed measuring, and detection of other objects in a certain automotive system. They have found widespread use in vehicle assembly to indicate the locations of parts, for example, doors, tires, motors and tell if these items are set for use in the next stage.

In addition, inductive sensors are widely used in vehicle safety equipment such as anti-lock brakes (ABS) equipped cars, airbag systems, or even parking sensors.

The sensors provide various data that keep the vehicle components and systems safe and efficient. This is done to make sure that all requirements are attended to.

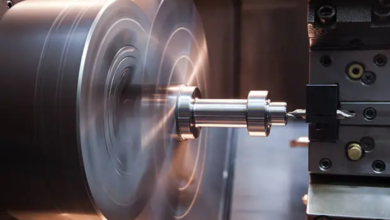

Robotics and CNC Machines

Both robots and CNC systems rely on inductive proximity sensors for accurate position or object detection in a robotic system. In robotic CNC systems, these sensors make sure that the arms of the robots are able to see where the parts are, hence, allow them to perform the specific task with precision. In a broad sense with CNC machines, they are able to use inductive sensors to find out where the tools as well as workpieces are. The accurate location of the sensors enables guiding the machining processes improving its accuracy.

These sensors enable automated assembly, welding, packaging, inspection and other processes with little or no human input at all hence increasing the speed of work relative to the error margin.

Advantages of Inductive Proximity Sensors

Inductive proximity sensors offer several advantages over traditional mechanical sensors, which make them a preferred choice in many industrial applications:

Non-contact Operation

Inductive sensors detect objects without physical contact, which significantly reduces wear and tear over time. This leads to longer service life, lower maintenance costs, and increased reliability in high-speed operations.

High Speed and Accuracy

Inductive proximity sensors provide fast response times, making them ideal for high-speed automation and manufacturing environments. Their ability to detect objects quickly and accurately allows for improved precision and efficiency in automated processes.

Durability and Reliability

Inductive proximity sensors are highly durable and can operate in harsh environments where other sensors might fail. They are resistant to dust, moisture, and other environmental factors, making them suitable for industries with challenging working conditions, such as automotive, food processing, and mining.

Cost-effective and Maintenance-free

Since inductive sensors have no moving parts, they require minimal maintenance, reducing the overall cost of ownership. Their durability also ensures a long operational life, making them an excellent investment for industrial systems that require high reliability.

Versatility

Inductive proximity sensors are versatile and can be used to detect a wide range of metal objects in various industrial applications. Whether it’s detecting small metal parts in a conveyor system or ensuring the proper position of a component in an assembly line, inductive sensors can be tailored to meet specific detection needs.

Conclusion

Inductive proximity sensors are a reliable, accurate, and durable solution for a wide range of industrial applications. Their ability to detect metallic objects without physical contact makes them an essential component in industrial automation, manufacturing, robotics, packaging, and many other sectors. The advantages of inductive sensors—such as non-contact operation, high speed, and long-lasting performance—make them a cost-effective choice for businesses seeking to optimize their operations, improve precision, and reduce maintenance costs.

By choosing the right inductive proximity sensor for your specific application, you can ensure higher efficiency, reduced downtime, and enhanced operational reliability. If you’re looking for high-quality and dependable proximity switches, OMCH offers a wide range of products designed to meet the demands of various industries.