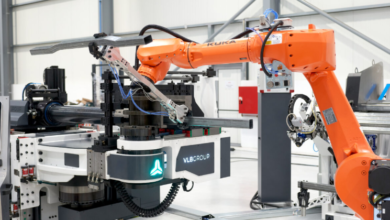

Enhancing Precision in Sheet Metal Fabrication

Introduction

Achieving precision in sheet metal bending is critical for quality and efficiency in modern fabrication. Accurate bends reduce material waste, improve assembly fit, and ensure the final product meets specifications. A key component that ensures consistent bending is the back gauge for press brake, which allows operators to position metal sheets precisely before bending. Understanding how this tool works, its types, and its applications can significantly improve production outcomes.

What is a Back Gauge for Press Brake?

A back gauge for press brake is a device installed at the rear of a press brake machine that controls the position of the sheet metal. Its primary function is to provide a reference point for the metal, ensuring each bend occurs at the exact location. Back gauges can be mechanical or CNC-controlled, with CNC models offering higher accuracy, automation, and repeatability.

Types of Back Gauges

Manual Back Gauges

Manual back gauges are simpler and cost-effective. Operators adjust the position physically, making them suitable for small-scale production or simple bends. However, they may introduce human error and require careful measurement to maintain accuracy.

CNC Back Gauges

CNC-controlled back gauges use computerized systems to position metal sheets automatically. They can move in multiple axes and handle complex bending patterns efficiently. CNC back gauges reduce operator intervention, increase production speed, and maintain high accuracy, especially in high-volume manufacturing.

Multi-Axis Back Gauges

Advanced press brakes may incorporate multi-axis back gauges. These devices allow adjustments along several directions, enabling intricate bends, offsets, and combination bends in one setup. Multi-axis back gauges are especially useful in industries where precision is critical.

Advantages of Using a Back Gauge

Improved Accuracy

Back gauges ensure that each bend occurs at the exact position, reducing errors and maintaining consistency across multiple parts.

Increased Efficiency

Automated back gauges minimize manual back gauge for press brake measurement, speeding up production cycles and allowing operators to focus on other tasks.

Reduced Material Waste

Precise positioning reduces errors and scrap, lowering material costs and improving overall resource utilization.

Enhanced Safety

Back gauges reduce the need for operators to handle metal sheets manually, decreasing the risk of injury during the bending process.

Versatility

Adjustable back gauges can accommodate different sheet sizes, thicknesses, and materials, making them suitable for various fabrication tasks.

See also: The Techniques of CNC Turning for Precision Components: Exploring Advanced Techniques

Applications in Different Industries

Automotive Manufacturing

In the automotive industry, components like panels, brackets, and chassis parts must meet strict tolerances. Back gauges ensure uniformity, contributing to better fit and performance.

Aerospace Fabrication

Aircraft components require precision and reliability. Back gauges allow accurate bending of structural and functional parts, ensuring safety and performance standards.

Construction and Architecture

Metal elements used in construction, including support structures and decorative panels, benefit from the accuracy provided by back gauges, reducing errors in large-scale projects.

Consumer Goods Production

Appliances, furniture, and metal housings require consistent bends for both functionality and aesthetics. Back gauges help maintain product quality and reduce rework.

Factors Affecting Performance

The efficiency of a back gauge depends on several factors:

- Material Thickness: Thicker sheets may need specific adjustments.

- Machine Calibration: Proper alignment ensures precise positioning.

- Operator Skill: Knowledgeable operators can maximize the benefits of the gauge.

- Maintenance: Regular checks and lubrication prevent mechanical issues.

- Programming Accuracy: Correct CNC programming is essential for repeatable bends.

Best Practices for Using a Back Gauge

- Calibrate and align the back gauge before production.

- Use CNC settings for complex or multi-step bends.

- Regularly inspect and maintain moving parts to ensure smooth operation.

- Train operators on proper setup and adjustment techniques.

- Monitor bends and adjust gauge positions as needed during production runs.

Technological Advances

Modern back gauges have incorporated advanced features:

- Adaptive Positioning: Some systems adjust automatically based on real-time feedback.

- Touchscreen Controls: Simplify programming and operation.

- Integration with CAD/CAM: Enables direct translation of design specifications into precise gauge positions.

- Predictive Maintenance: Sensors detect wear or misalignment, preventing errors before they occur.

Economic Benefits

Investing in high-quality back gauges offers financial advantages:

- Lower Scrap Rates: Accurate bends reduce material waste.

- Faster Production: Automation reduces cycle time.

- Consistent Quality: Decreases rework and defects.

- Extended Tool Life: Proper positioning minimizes stress on press brake tooling.

Conclusion

A back gauge for press brake is essential for modern metal fabrication, offering precision, efficiency, and safety. By understanding its types, benefits, and applications, manufacturers can improve production quality, reduce waste, and optimize operations. As technology advances, back gauges will continue to play a critical role in achieving high-precision, consistent, and efficient bending processes.