Tire Cutting: The Precision of Diamond Wire Loop Cutting

Tire cutting has evolved far beyond crude mechanical methods. As modern industries demand cleaner edges, tighter tolerances, and higher efficiency, advanced cutting technologies have stepped in to redefine what precision really means. Among these innovations, diamond wire loop cutting has emerged as a game-changer, especially for applications involving dense, reinforced rubber materials like tires. Understanding how this method works and why it matters can help manufacturers and recyclers make smarter, more profitable decisions.

Understanding Modern Tire Cutting Challenges

Tires are not simple materials. They are complex composites made of rubber, steel belts, fabric layers, and chemical additives, all bonded together under extreme pressure. Traditional cutting methods often struggle with this combination, leading to uneven cuts, excessive tool wear, and wasted material. Heat buildup is another common issue, which can deform rubber edges and compromise downstream processing.

This is why Tire Cutting requires a solution that is both strong and precise. Accuracy is not just about aesthetics; it directly impacts recycling efficiency, component separation, and overall production costs. A cleaner cut means less rework, fewer rejects, and smoother handling in later stages.

Why Diamond Wire Loop Cutting Stands Out

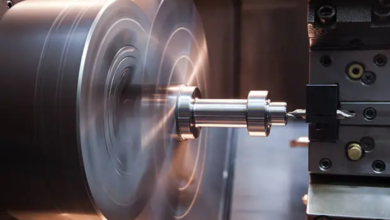

Diamond wire loop cutting operates on a fundamentally different principle than blades or saws. Instead of forcing a rigid edge through the material, a flexible loop embedded with industrial diamonds gently grinds through the tire structure. This results in a controlled, low-vibration process that maintains consistent cutting accuracy even with reinforced tire sections.

Precision Without Excessive Force

One of the biggest advantages of this technology is how little mechanical stress it applies. The wire conforms slightly as it moves, allowing it to navigate steel cords and layered rubber without sudden resistance. This leads to straighter cuts and significantly reduces the risk of tearing or fraying along the edges.

Cleaner Cuts and Better Material Recovery

In recycling and retreading operations, clean separation is critical. Diamond wire loop cutting produces smooth surfaces that make it easier to sort rubber, steel, and textile components. Over time, this translates into higher recovery rates and improved material quality, which directly affects profitability.

The Role of Semi-Coated Diamond Loop Wire

Not all diamond wires are the same, and this is where Semi-Coated Diamond Loop Wire becomes especially relevant. The semi-coated design strikes a balance between cutting aggressiveness and durability. By partially coating the diamond surface, the wire maintains sharp cutting points while protecting the bond that holds the diamonds in place.

This balance is crucial in tire cutting environments, where abrasive rubber compounds and steel reinforcements can quickly degrade fully exposed wires. Semi-coated options last longer, cut more consistently, and reduce downtime caused by frequent wire replacements. For operations running continuous or high-volume cutting lines, this reliability can make a measurable difference in output.

Ensolltools and Its Relevance in Precision Tire Cutting

Ensolltools has built a strong reputation by focusing on cutting solutions that combine durability with precision. In the context of tire cutting, the brand’s approach emphasizes material compatibility and long-term performance rather than short-term speed alone. By offering diamond wire loop solutions designed specifically for demanding applications, Ensolltools supports manufacturers who need consistent results across varied tire compositions.

What makes Ensolltools particularly relevant is its attention to wire construction quality. The balance between flexibility, diamond exposure, and coating strength aligns well with the requirements of modern tire processing facilities. This ensures smoother operation, reduced maintenance interruptions, and predictable cutting behavior over extended use.

See also: How Managed Hosting Reduces Technical Stress for Store Owners

Applications Across Recycling and Manufacturing

Diamond wire loop cutting is not limited to one niche. It is used in tire recycling plants for size reduction, in manufacturing environments for prototype cutting, and even in research settings where precise sectioning is required. In all these cases, the same benefits apply: controlled cuts, minimal material damage, and efficient energy use.

As sustainability becomes a larger priority, accurate tire cutting also plays a role in reducing waste. Efficient separation makes recycling processes more viable and environmentally responsible, which is increasingly important for companies facing stricter regulations.

The Future of Tire Cutting Technology

The future of tire cutting lies in smarter, more adaptive tools. Diamond wire loop systems, especially those using semi-coated designs, are well positioned to meet these demands. As materials evolve and tires become even more complex, flexible precision cutting will continue to outperform rigid alternatives.

Manufacturers that invest in advanced cutting solutions today are better prepared for tomorrow’s challenges. By focusing on accuracy, longevity, and material integrity, they can improve both operational efficiency and product quality.

Conclusion

Tire Cutting is no longer just about getting through tough rubber; it is about doing so with precision, consistency, and efficiency. Diamond wire loop cutting offers a refined approach that addresses the unique challenges of tire materials, while Semi-Coated Diamond Loop Wire enhances durability and performance in demanding conditions. With brands like Ensolltools contributing specialized solutions to this space, industries now have access to cutting technologies that deliver cleaner results, longer tool life, and better overall value. As precision continues to define competitive advantage, diamond wire loop cutting stands out as a smart, future-ready choice.