What Should You Know About Sourcing Integrated Circuits?

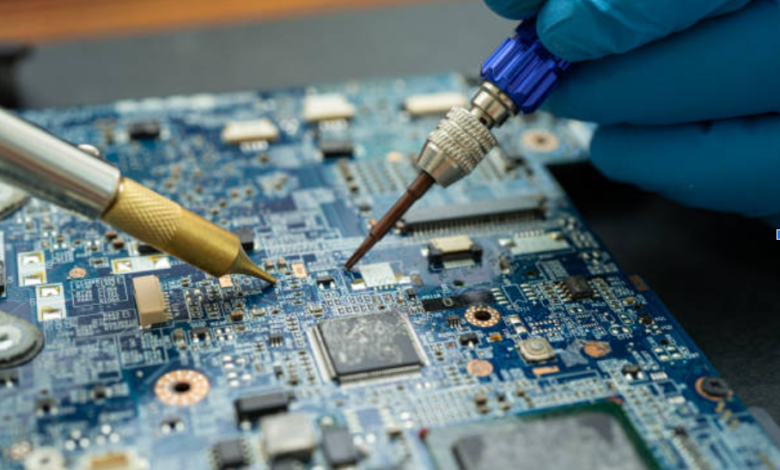

Integrated circuits (ICs) are the heartbeat of virtually every modern electronic device. From smartphones and automotive systems to industrial equipment and aerospace technologies, these tiny chips are responsible for managing complex tasks and ensuring reliable system performance. With such critical functionality tied to these components, understanding the ins and outs of integrated circuit sourcing is essential for design engineers, procurement professionals, and manufacturers alike.

Understanding the Importance of Integrated Circuits

Integrated circuits combine thousands to billions of transistors into a compact package, allowing for efficient processing, memory storage, signal amplification, and communication functions. They are foundational to the operation of CPUs, GPUs, sensors, power management systems, and more.

Due to their ubiquity and complex manufacturing process, disruptions in the supply of ICs can paralyze production lines and delay product launches. This makes integrated circuit sourcing a vital strategy rather than just a procurement task. Knowing where, how, and from whom to source ICs can be the difference between a smooth project lifecycle and costly delays.

Challenges in Integrated Circuit Sourcing

One of the most critical obstacles encountered in sourcing integrated circuits is the market instability. The high demand, geopolitical tensions, or limited production capabilities at semiconductor foundries often lead to ICs having supply chain bottlenecks. A case in point is the worldwide chip deficit that erupted in 2020, causing countless industries to suffer for years and emphasizing the semiconductor supply chains’ vulnerability.

Counterfeit components pose yet another challenge. As ICs constitute valuable components, counterfeit producers take advantage of this market by vending falsely labeled or dysfunctional chips, particularly in the midst of shortages. These fake components can result in system failures, security vulnerabilities, and even safety issues.

To deal with these problems, reliable integrated circuit sourcing has to involve supplier verification, traceability, and component testing. This can also be achieved by working with authorized distributors or directly with manufacturers that, in turn, would, in addition to product availability, help to ensure a product’s authenticity.

See also: Advantages of Optical TPU Technology for Clear Bra Owners

Supplier Relationships and Long-Term Planning

The integrated circuit sourcing process hinges predominantly on establishing a secure reciprocal relationship with trustworthy suppliers. Supplier allocation of inventory for priority customers is effectively ensured through long-term contracts, preferred partner programs, and forecasts being communicated clearly.

A further benefit is that the design engineers now have the procurement teams involved at an early stage of the product development cycle. If sourcing is taken into account when starting the design process, engineers may select new components more effectively, the aspects that are optimal in performance and widely available over pthe roduct lifespan.

In addition to this, a choice of components with multi-sourcing or second-source equivalents provides flexibility and resilience when a primary vendor is disturbed.

The Role of Lifecycle Management

All input circuits have a product life cycle—introduction and growth to maturity, and obsolescence. Lifecycle management in integrated circuit sourcing mutual neglect is far worse, especially with sectors like aerospace or medical technology, which have products that should last more than a human lifetime.

The use of neo-Gothic or obsolete (EOL) components can lead to project delay, cost demur for the mandatory requalification testing, or even a complete production shutdown. Manufacturer notifications, along with lifecycle management, proactive strategy tracking, ensure the provision of the right replacements or long-term inventories when needed.

Regional Considerations and Global Trends

Geopolitical events and tariffs, particularly where they are manufactured, often prompt scarcity of specific integrated circuits. Components produced in some regions may be export-controlled or embargoed, making things even more complex for worldwide players.

Risk can be mitigated and production continuity sustained by diversifying sources geographically. This is both a response to the risk of supply chain disruptions and a trend among manufacturers to move toward more resilient and localized supply chains, thereby decreasing dependence on any one region.

Quality, Compliance, and Certification

ICs deployed in the aerospace, military, automotive, and industrial sectors are required to adhere to strict quality and compliance mandates. Sourcing components that are certified under ISO, RoHS, REACH, and other standards is one way of ensuring not only legal compliance and that obsolescence is not an issue. In the process, reliability, safety, and long-term performance are also assured.

Supplier processes, auditing, datasheet verification, and procurement of certificates of conformance constitute due diligence in the integrated circuit sourcing process. Ignoring these particular conditions can, however, lead to, among other things, product recalls, liability claims, or even rejection by regulatory bodies.

Digital Tools and Inventory Management

Digital tools are the mainstay of modern procurement strategies, which are, for instance, deployed in integrated circuit sourcing. Real-time data on chip availability, lead times, pricing, and alternatives is delivered by platforms like Octopart, FindChips, and supply chain management software.

The integration of these tools within the procurement systems will mean faster decision-making, automated stock level alerts, and an improved forecast. This proactive strategy will help firms to prevent the occurrence of potential shortages and thus respond to the demand fluctuations more efficiently.

Conclusion

Integrated circuits are central to nearly every electronic system, and the process of integrated circuit sourcing has become a critical strategic function. Navigating supply chain challenges, ensuring quality, managing component lifecycles, and leveraging digital tools are all necessary for successful sourcing. As technology advances and demand for ICs continues to rise, companies that invest in intelligent sourcing practices will be better positioned to deliver innovative, reliable, and timely products.