The Techniques of CNC Turning for Precision Components: Exploring Advanced Techniques of Machining Parts

When it comes to B2B manufacturing, the most crucial factors include tolerances, material properties, and process optimization. CNC turning has enabled the automation of manufacturing processes involving cylindrical and round parts—also known as turned components—and taken them to a whole new level.

This article is about how advanced CNC techniques are turning the production of precision machining parts into an effortless routine for manufacturers in medical, aviation, automotive, and robotics industries. Such industry updates will greatly assist B2B decision-makers when planning and budgeting for resources, purchasing, and production.

The Uses of CNC Turning Along with Other Methods in Precision Manufacturing

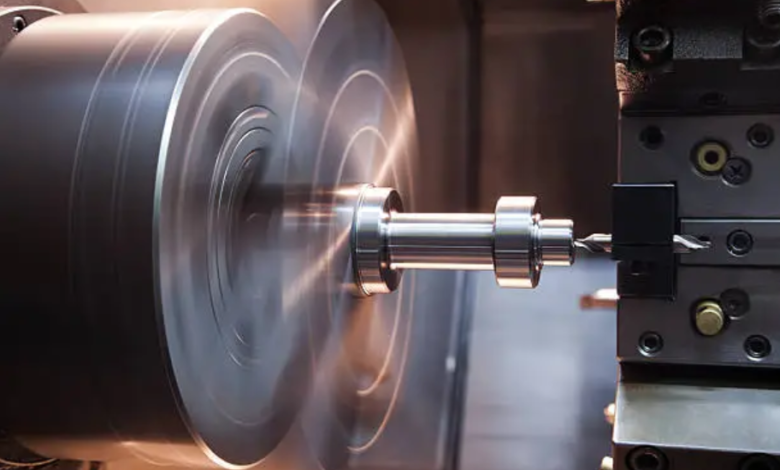

CNC turning is a machining method in which tool bits are used to cut geometrically precise dimensions of cylindrical areas in rotating workpieces such as shafts, bushings, and rotary connectors, along with other round profile peripherals requiring high standards of surface quality, micro finishing, and clear definitions.

In contrast to milling, which employs a fixed workpiece and a rotating tool, CNC turning boasts a fixed tool or one that moves along designated axes as the material spins in the CNC machine. This particular configuration provides multiple benefits in regards of symmetry, efficiency, and detailed work—particularly in complex inner and outer diameters.

When produced by adept turned parts manufacturers, these components often serve as mission-critical parts in systems where unconditional dependability, steadfastness, and superior performance are paramount.

See also: Advantages of Optical TPU Technology for Clear Bra Owners

Advances in CNC Turning Technology

At the same time, other CNC turning processes have experienced immense growth, particularly with advancements in technology directing focus towards precision and volume throughput. The following list includes a few of the more noteworthy changes directing the advancement of precision machining parts becoming more readily available via CNC turning.

Multi-Axis Turning Centers

Conventional lathes were limited to two axes of operation: X (radial) and Z (longitudinal). The modern approach to turning centers adds up to 9 axes of operation, enabling complex geometries, off-center drilling, and even some milling—all in one setup. This single-unit multitasking capability greatly cuts down on setup time and user error introduced from repositioning the part.

Multi-axis machines can manufacture a wide range of geometry, including undercuts and threads, that would otherwise be difficult or beyond the skill of standard equipment. This capability enhances design freedom for B2B companies without offsetting manufacturability.

Live Tooling Capabilities

Leveraging live tooling means that both turning and milling operations can be done simultaneously on a single machine. CNC lathes are now able to perform drilling, slotting, and forming of surface flats and grooves with their powered rotary tools which are CNC controlled, no longer are these activities limited to milling centers.

This method will improve tolerances in multi-feature components because it minimizes time and reduces machine idle time.

Swiss-Type Lathes for Micro-Precision

Electronics, medical instruments, and other high-performance assemblies greatly benefit from the small, slender parts CNC Swiss-type lathes offer. With the use of sliding headstock, this machine keeps the workpiece closer to the cutting tool, thus deflection and concentricity is improved.

Swiss lathes are conventional equipment for turned parts manufacturers that rely on mass production of micro-scale precision machining parts because in many applications, any deviation no matter how small renders the part useless.

Automation and Smart Monitoring

Modern CNC turning machines are fully equipped with IoT sensors and Artificial Intelligence monitoring systems. Active monitoring allows for real time updates on aspects of the machine including tool wear, vibration, temperature, and spindle load which are important for maintenance measures and quality assurance.

B2B customers that seek to control machine off-cycles while trying to reduce operational waste are targeted by the advanced monitoring systems. These smart tools allow assurance that parts are made to consistently high standards.

Materials and Surface Finishing Options

The versatility of CNC Turning goes beyond the geometry and includes the range of materials and finishing processes that can be used.

Common Materials Used

- Stainless steel: As an alloy, it is properly used in application as it is highly durable and corrosion resistant especially in Aerospace and Medical Industries.

- Aluminium: Due to its light weight and excellent machinability, it is often used in automobiles and consumer electronics.

- Brass and Copper: Highly known for their conductivity and eye appealing finish, they are used for the electrical fittings and components.

- Engineering plastics: Range of chemical resistive materials and lightweight performance in automation equipment makes them useful.

All of these materials can be custom manufactured into components that fulfill certain criteria such as hardness, wear resistance and thermal stability.

Finishing Techniques

Post-processing of the components is a crucial part of making the part work better and look better therefore some of the known post processing methods are:

- Anodizing

- Polishing

- Electroplating

- Passivation

- Bead Blasting

Regardless of the method used, all of the above improve resistance to corrosion, friction, and yield decorative outcomes.

Applications Across Important B2B Sectors

The innovation of CNC turning has broadened its use to almost every sector that relies on precision. Let’s examine its application in various B2B industries:

Aerospace and Defense

Instruments for hydraulic systems, engines, and landing gear assemblies in aerospace utilize CNC turned parts. These components have to fulfill military or FAA certifiable documents, and must pass numerous industrial standards which make CNC turning highly useful.

Medical and Surgical Equipment

Surgical tools, implants, and orthopedic tools require both biocompatibility and extremely tight tolerances. CNC turning is capable of fulfilling, under very strict industry regulations, the precision required.

Automotive and E-Mobility

CNC turned parts aid in the performance, weight, and durability of components ranging from steering and drivetrain parts to EV battery connectors. This precision is necessary for enduring fuel efficiency and safety standards.

Electronics and Connectors

Electrical devices like plugs, pins, and contacts have finely detailed parts that are produced through electrical device high speed turning. They are usually manufactured in large quantities and turned copper or brass components are exemplary when it comes to conductivity.

Automation and Robotics

Motion shafts, connector housings, and robotic joints all depend on turned parts. For automation original equipment manufacturer CNC turning has allowed prototyping and producing with dependable, short relative dates between the request and delivery.

Picking the Ideal Partner for Turned Part Manufacturing

Selecting a partner for CNC turning is one of the most important decisions, as it affects cost, quality, and timelines greatly. For B2B sourcing professionals, the following points are of importance:

Technical Considerations

Does the supplier own multi-axis lathes, live tooling, and micro-machining systems? Equipment range and level directly impact the complexity of a part and its production volume.

Quality Assurance

As a vendor, they should have ISO 9001 or equivalent international quality certifications and possess CMMs (Coordinate Measuring Machines) and other tools for dimensional verification.

Industry Materials Knowledge

Different industries require different material competencies. A supplier specializing in certain industry materials may not be useful, so check their material proficiency relevant to your product line.

Customization and Volumetric Flexibility

The right supplier should accommodate quantity flexibilities, responsive quoting, and other speed options for rapid delivery and low-quantity prototyping and mass production.

Communication

Proper communication reduces chances of a design being miscommunicated and mis implemented. Seek providers who help with comment, feedback, tolerance suggestions, or other complete production traceability support.

Conclusion: The Future of CNC Turned Components

The CNC turning development is still influencing the landscape of precision machining parts, further enabling intricacy, efficiency, and detail. Businesses—especially those in harsh or regulated environments—are finding immense value in collaborating with seasoned turned parts manufacturers, as the demand for high-performance mechanical components continues to surge.

CNC turning will become even more cost-effective and efficient as technologies like AI, automation, and hybrid machining converge. With the CNC techniques’ increasing prowess, mastering the science of seamless scalability, turned parts, and CNC systems makes for a strategic business move.