Smart mockups improve CNC turning accuracy reducing prototype iteration costs by 40%

Introduction

In the precision manufacturing industry, prototype design is often plagued by multiple iterations due to a lack of effective visualization tools, leading to significant time and cost overruns. Engineers frequently encounter design mismatches and tolerance exceedances during the CNC turning process. The core issue lies in traditional methods’ reliance on physical prototypes, which fail to allow for pre-production simulation of assembly or aesthetics, resulting in high costs and delays.

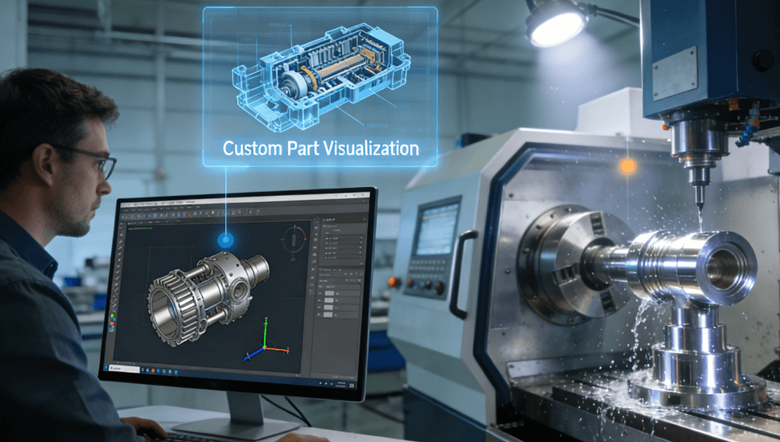

This article introduces a solution that combines the digital power of Smart Mockups with CNC turning technology, enabling design optimization through virtual simulation. The following sections will detail how this integrated approach is transforming prototype development.

What is CNC Turning, and How Does it Benefit from Prototype Design Mockups?

What is CNC turning? It is a fundamental subtractive manufacturing process where a cutting tool moves in a linear path while the workpiece rotates at high speed. This method is ideal for creating cylindrical or conical parts with high dimensional accuracy. The effectiveness of precision CNC turning hinges on the precise control of factors like rotational speed, feed rate, and cutting depth.

The integration of Prototype Design Mockups brings a transformative advantage to this process. These digital mockups provide a dynamic 3D visualization of the final part long before any material is cut. Engineers can simulate the appearance, fit, and function of a CNC turning component within a larger assembly. This virtual validation helps identify interferences, assess clearances, and verify that designs are manufacturable, drastically reducing the dependency on physical prototypes. A report from The Manufacturing Institute emphasizes that digital simulation is no longer a luxury but a necessity for staying competitive in modern manufacturing, as it slashes both time-to-market and development costs.

For instance, in producing Aluminium CNC turning parts, a digital mockup can preemptively detect thermal expansion issues or tool path conflicts that might lead to tolerance violations. By visualizing the part in a simulated environment, manufacturers can adjust machining parameters upfront, ensuring the final product meets the stringent specifications required for high-performance applications, thereby elevating the overall quality and precision of the outcome.

See also: Upgrade Flooring to Attract Potential Home Buyers

Why are CNC Machining Simulations Crucial for Rapid Prototyping Designs?

Simulation technology is the backbone of modern rapid prototyping, providing a virtual testing ground that predicts real-world manufacturing outcomes. Its role in Rapid Prototyping Designs is indispensable for achieving speed, accuracy, and cost-efficiency.

Predicting Material Behavior and Optimizing Tolerances

CNC Machining Simulations allow engineers to foresee how a material will behave under the stress of cutting tools. This is particularly critical for Rapid Prototyping Designs, where the goal is to iterate quickly without sacrificing quality. Simulations can predict potential issues like chatter, deflection, or overheating, which are common causes of tolerance deviations. By addressing these issues virtually, manufacturers can ensure that the first physical prototype is much closer to the final design, significantly accelerating the development cycle.

Enhancing Efficiency and Reducing Waste in the CNC Turning Center

The core of simulation lies in its ability to optimize the entire machining process within a CNC turning center.

- Optimizing Tool Paths:

Simulations create the most efficient tool paths, minimizing unnecessary movements, reducing machining time, and extending tool life. This optimization is vital for controlling costs in rapid prototyping. - Mitigating Deformation Risks:

For delicate materials like aluminium, improper machining can cause deformation. Simulations can identify stress concentrations and potential warping in aluminium CNC turning parts, allowing for preemptive corrections in the toolpath or fixturing strategy.

Research published in the International Journal of Advanced Manufacturing Technology confirms that the use of advanced simulations can improve machining efficiency by over 30% and reduce scrap rates by up to 25%. For a deeper dive into best practices, a comprehensive resource like this Aluminium CNC Turning Guide can be invaluable for engineers.

The Data-Driven Advantage

The quantitative data generated from simulations—such as cycle time estimates, stress distribution maps, and thermal profiles—provides an objective basis for design improvements. This data-driven approach removes guesswork, enabling more informed decision-making during the prototyping phase.

How to Optimize Aerospace Component Mockups with Custom Part Visualizations?

The aerospace industry demands the highest levels of precision and reliability for components that must withstand extreme conditions. Here, Custom Part Visualizations become a critical tool for ensuring the integrity of Aerospace Component Mockups.

Aerospace components often feature complex, lightweight geometries that are challenging to manufacture. Custom Part Visualizations enable engineers to conduct virtual tests, such as computational fluid dynamics (CFD) for airflow analysis or finite element analysis (FEA) for stress distribution under load. By simulating these conditions on the digital mockup, potential failure points can be identified and rectified before any costly physical production begins. This process is essential for achieving the level of precision CNC turning required for flight-critical parts.

Companies which operate under stringent quality management systems like ISO 9001 and AS9100D, leverage these visualizations to guarantee that every component meets rigorous aerospace standards. While China’s manufacturing sector offers significant cost advantages for china CNC turning, it is the marriage of these cost benefits with advanced digital verification tools that ensures both affordability and uncompromising quality for aerospace clients.

Which CNC Turning Techniques Ensure Safety and Compliance in Medical Device Prototypes?

The development of Medical Device Prototypes is governed by strict regulatory requirements concerning biocompatibility, sterility, and dimensional accuracy. Even microscopic deviations can lead to device failure, making precision paramount.

Meeting Stringent Medical Standards

Medical Device Prototypes must adhere to standards that ensure patient safety. This involves using certified materials and processes that guarantee biocompatibility and dimensional stability. Precision CNC turning is ideally suited for this task, capable of machining intricate, miniature components from approved materials with tolerances within microns.

The Role of Precision Machining and Virtual Verification

Advanced CNC turning techniques are employed to manufacture small-scale medical parts, such as components for surgical instruments or implantable devices.

- Micro-Machining Capabilities:

Modern CNC turning centers can perform micro-machining, creating extremely fine features essential for medical technology. The process is validated through digital mockups that simulate assembly and function. - Material Selection and Validation:

Choosing the correct material, such as specific grades of aluminium or titanium, is critical. Custom Part Visualizations help verify that the chosen material and design will perform as intended in a biological environment.

Adherence to certifications like IATF 16949, which is pivotal for medical-grade manufacturing, underscores a supplier’s commitment to quality. For companies requiring such high-assurance production, engaging a partner with proven expertise in precision CNC turning services is a critical step toward achieving compliance and ensuring patient safety.

Ensuring Traceability and Quality

Beyond machining, a robust quality management system ensures full traceability of materials and processes, which is a non-negotiable requirement for regulatory approval of medical devices.

How to Integrate Rapid Prototyping Designs to Control Costs in the China CNC Turning Environment?

The Chinese manufacturing landscape is renowned for its robust supply chain, rapid response capabilities, and cost-effectiveness. To fully leverage these advantages for Rapid Prototyping Designs, a strategic integration of digital tools is key.

Integrating digital Prototype Design Mockups within the china CNC turning workflow allows for rapid iteration at a fraction of the traditional cost. Designers can test multiple versions virtually, identifying the optimal design before committing to physical production. This approach significantly reduces material waste, which is especially beneficial when working with commodities like aluminium. This aligns with sustainable manufacturing practices, often formalized through certifications like ISO 14001.

By using these digital tools, companies can compress the design-to-production timeline, allowing a CNC turning center in China to begin manufacturing a validated design almost immediately. This synergy between cost-efficient manufacturing and digital acceleration provides global clients with a compelling value proposition: high-quality Rapid Prototyping Designs delivered with competitive pricing and shortened lead times, without compromising on the precision or reliability of the final parts.

Conclusion

In summary, the integration of Smart Mockups’ visualization capabilities with CNC turning technology presents a paradigm shift in prototype development. This fusion enhances precision, drastically reduces iteration costs, and accelerates time-to-market. The certified quality management systems ensure this process is reliable and consistent.

Ready to optimize your prototyping process? Contact today for a customized Aluminium CNC Turning solution and download a free Mockups template to start refining your designs with confidence.

Author Biography

The author is a precision manufacturing specialist with over a decade of experience in CNC turning and a focus on digital prototype optimization. This article is based on industry best practices and case studies from JS Precision.

FAQ Section

Q1: How complex of a geometry can CNC Machining Simulations handle?

A1: Advanced simulation tools can handle highly complex geometries, including those for aerospace components. They enable virtual testing to prevent physical errors, ensuring tolerances as tight as ±0.01mm for precision projects.

Q2: How to select the right aluminum for Medical Device Prototypes?

A2: Alloys like 6061 or 7075 aluminum are recommended for their strength and biocompatibility. Using Mockups to simulate the design helps verify compliance and safety before manufacturing.

Q3: How do Mockups save time in Rapid Prototyping Designs?

A3: Mockups enable virtual iterations in hours instead of days required for physical tests, speeding up decision-making. In a China CNC turning context, this can reduce the delivery cycle by up to 30%.

Q4: What is the maximum size a CNC Turning center can handle?

A4: Standard CNC turning centers can handle parts up to 500mm in diameter, though custom equipment exists for larger sizes. Using Mockups for pre-simulation helps optimize fixture design and prevent size conflicts.

Q5: Why are China CNC Turning services more cost-competitive?

A5: Integrated supply chains in China lower material and labor costs. When combined with digital Mockups that minimize waste, and suppliers like with ISO certifications ensuring quality, global clients receive high value.