Understanding Modern Bending Systems in Fabrication

Introduction to Metal Bending in Manufacturing

In modern fabrication, bending is a fundamental process that transforms flat metal sheets into functional components. Accurate bending is crucial for product reliability, structural integrity, and manufacturing efficiency. Factories across industries—from construction to automotive—rely on machines that provide precision and consistency to meet production standards.

This article explores the different bending systems available in the market, their uses, and their impact on industrial manufacturing.

Why Precision Matters in Bending

Metal components must maintain strength and shape to function properly. Even slight errors in bending angles or alignment can lead to defective parts or assembly issues. Using specialized machines ensures controlled force is applied, producing consistent results across multiple units.

Precision in bending also reduces waste and lowers production costs by minimizing the need for rework.

Overview of Industrial Bending Solutions

Bending machines vary in design, control systems, and application. Selecting the right machine depends on material type, thickness, production volume, and desired bend accuracy. Modern equipment often combines mechanical, hydraulic, or CNC-based systems for versatile operations.

Each system offers unique advantages suited to specific manufacturing requirements.

Mechanical Bending Machines

Mechanical bending machines operate using a simple lever or flywheel mechanism. They provide fast bending cycles and are cost-effective for small to medium production runs. These machines are suitable for thin metal sheets and simpler bends but have limitations in handling thicker materials or complex profiles.

Hydraulic Bending Machines

Hydraulic bending machines are powered by fluid pressure, offering higher force and precise control over bending angles. They can handle thicker materials and perform complex bends with uniform results. Their versatility makes them suitable for medium to large-scale production in industrial settings.

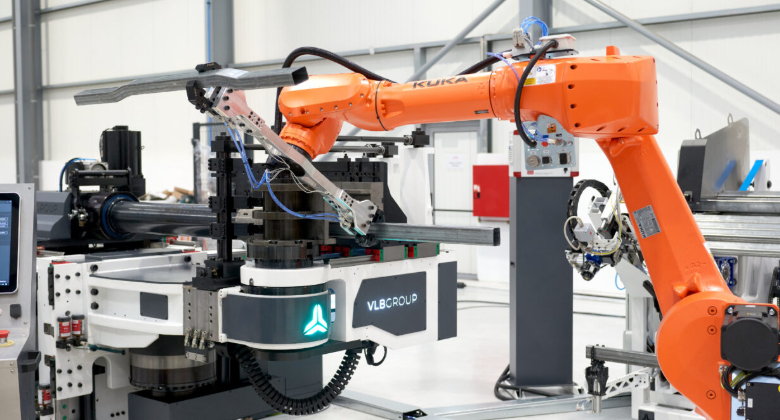

CNC Bending Machines

CNC (computer numerical control) bending systems allow operators to program exact bend sequences, angles, and positions. These machines, also referred to as types of press brakes, deliver high precision, repeatability, and automation. They are ideal for high-volume production or projects requiring intricate bend patterns. CNC systems reduce human error and improve overall workflow efficiency.

Electric and Hybrid Systems

Modern advancements have introduced fully electric or hybrid bending systems. Electric machines offer energy efficiency, minimal maintenance, and precise motion control. Hybrid systems combine electric and hydraulic features to provide both speed and power, making them adaptable for diverse manufacturing needs.

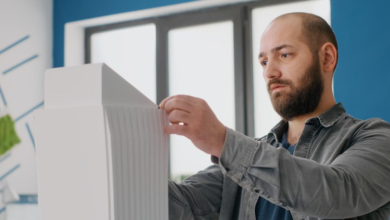

See also: Transforming Medical Office Interiors with 3D Modelling Technology

Considerations for Choosing the Right Machine

Selecting the appropriate bending system requires evaluating production needs:

- Material type and thickness

- Bend complexity and angle precision

- Production volume and speed requirements

- Available budget and maintenance capabilities

Understanding these factors ensures optimal machine performance and a strong return on investment.

Applications in Structural Fabrication

Structural fabrication projects require consistent bends for beams, brackets, and supports. Industrial bending systems ensure components meet engineering standards, maintain strength, and fit seamlessly during assembly. This accuracy is crucial in construction, manufacturing plants, and infrastructure projects.

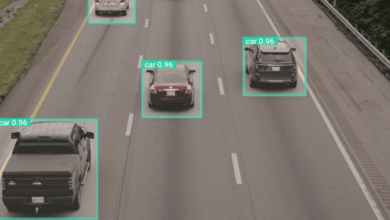

Automotive Industry Applications

The automotive sector relies on bent metal for frames, panels, and brackets. CNC and hydraulic bending machines provide the precision and repeatability needed for high-volume production. Accurate bends support vehicle safety, performance, and assembly efficiency.

Electrical Enclosures and Industrial Equipment

Metal enclosures for electrical systems and machinery require precise bends for proper alignment and protection. Bending systems produce clean edges and accurate dimensions, ensuring components meet functional and aesthetic standards.

Supporting Custom Fabrication and Prototyping

Custom fabrication often involves unique designs and small production runs. Mechanical, hydraulic, and CNC systems all play a role depending on the complexity of the project. CNC systems are particularly useful for prototypes due to programmable precision and repeatability.

Efficiency and Productivity Benefits

Using the right bending system enhances productivity by reducing setup time, rework, and material waste. Automated or CNC-controlled systems enable faster production cycles and consistent output quality.

Maintenance and Longevity

Routine maintenance is essential to ensure reliability. Regular inspections, lubrication, and timely replacement of worn parts prevent breakdowns and prolong the machine’s operational life.

Safety Considerations

Modern bending systems include safety features to protect operators. Guards, emergency stops, and controlled movement reduce the risk of accidents. Proper training and adherence to safety protocols further enhance workplace safety.

Future Trends in Bending Technology

Advancements in automation, smart controls, and energy-efficient systems are shaping the future of metal bending. Integration with digital manufacturing platforms and predictive maintenance ensures higher precision, reduced downtime, and more efficient production workflows.

Sustainability and Environmental Impact

Efficient bending processes reduce material waste and energy consumption. Modern systems are designed to optimize power usage and minimize environmental impact, aligning with industry goals for sustainable manufacturing.

Conclusion

Understanding the various bending systems allows manufacturers to select the right solution for their specific needs. Mechanical, hydraulic, CNC, and hybrid machines each have unique advantages, supporting different applications from structural fabrication to custom prototyping. Proper machine selection, maintenance, and operator training ensure consistent quality, cost efficiency, and safe operations.

By leveraging the right bending technology, manufacturers can meet industry standards, enhance productivity, and prepare for future advancements in fabrication.